Cold Stamped Carbon Steel

Author:ALEX

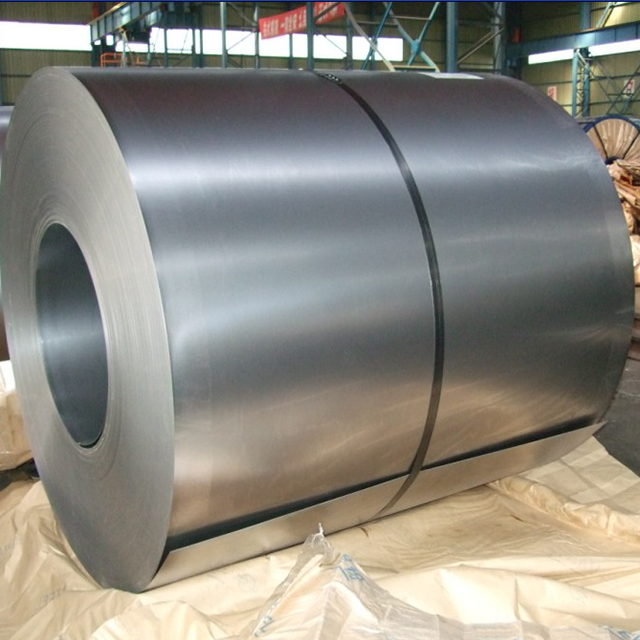

Cold Stamped Carbon Steel

Abstract

The article aims to provide a comprehensive understanding of  cold stamped carbon steel, exploring its properties, applications, manufacturing process, and future prospects. By delving into the topic, readers can gain valuable insight into this material and its potential in various industries.

cold stamped carbon steel, exploring its properties, applications, manufacturing process, and future prospects. By delving into the topic, readers can gain valuable insight into this material and its potential in various industries.

Introduction

Cold stamped carbon steel has gained significant attention in recent years due to its exceptional mechanical properties and cost-effectiveness. This article aims to shed light on this material by discussing its properties, production process, applications, and future prospects. By exploring these aspects in detail, readers can appreciate the immense potential that cold stamped carbon steel offers across multiple industries.

Text

1. Properties of Cold Stamped Carbon Steel

Cold stamped carbon steel possesses remarkable physical and mechanical properties that make it a preferred choice in various applications. First, its high strength-to-weight ratio provides excellent structural integrity while keeping the weight of components low. Second, the material exhibits superior corrosion resistance, making it suitable for applications in harsh environments. Third, cold stamped carbon steel offers excellent formability, allowing manufacturers to create intricate shapes and designs. Lastly, the material showcases exceptional fatigue resistance, ensuring long-term reliability and durability.

2. Manufacturing Process of Cold Stamped Carbon Steel

The production of cold stamped carbon steel involves several stages. Firstly, high-quality carbon steel sheet is selected as the base material, ensuring optimal properties for the final product. The sheet is then cleaned and prepared to remove impurities, enabling a smooth and uniform surface. Subsequently, the material undergoes a stamping process where it is formed using high-precision dies and presses. This process imparts the desired shape and dimension to the carbon steel, ensuring accurate and consistent components. Finally, the cold stamped carbon steel components undergo various finishing treatments, including heat treatment and surface coatings, to enhance their mechanical properties and protect against corrosion.

3. Applications of Cold Stamped Carbon Steel

The versatility of cold stamped carbon steel allows for its application in a wide range of industries. In the automotive industry, it is extensively used for the production of structural components, such as chassis parts and body panels, owing to its high strength and lightweight nature. Additionally, cold stamped carbon steel finds applications in the construction industry for the manufacturing of support structures, beams, and columns. The electrical and electronics industry also benefits from this material, utilizing it for the production of enclosures, connectors, and electrical components. Furthermore, cold stamped carbon steel is employed in the manufacturing of consumer goods, including appliances and furniture, due to its aesthetic appeal and durability.

4. Future Prospects of Cold Stamped Carbon Steel

The future of cold stamped carbon steel appears promising, as advancements in material science and manufacturing techniques continue to enhance its properties and expand its application areas. Research is ongoing to optimize the alloy composition of carbon steel, aiming to further improve its strength, corrosion resistance, and formability. Moreover, innovations in stamping processes, such as advanced tooling and automation, will streamline production and reduce costs. With these developments, cold stamped carbon steel is poised to play a vital role in the advancement of industries, offering sustainable and efficient solutions.

Conclusion

In conclusion, cold stamped carbon steel possesses exceptional properties, making it a valuable material in various industries. Its high strength-to-weight ratio, corrosion resistance, formability, and fatigue resistance contribute to its widespread use in automotive, construction, electrical, and consumer goods sectors. The manufacturing process of cold stamped carbon steel ensures accurate and consistent components, further enhancing its appeal. With continuous research and technological advancements, the future of cold stamped carbon steel looks promising, presenting opportunities for further improvements in properties and expanding its application areas. The potential of this material to contribute to sustainable and efficient solutions is undeniably significant.

add your comment