Does decarburized steel rust

Author:ALEX

Does decarburized steel rust?

Abstract:

This article aims to explore the question of whether decarburized steel rusts. By providing background information and arousing readers' interest, it delves into the scientific factors behind the process of rusting in decarburized steel. Understanding this phenomenon is essential for industries that rely on steel products to make informed decisions regarding their materials and processes.

Text:

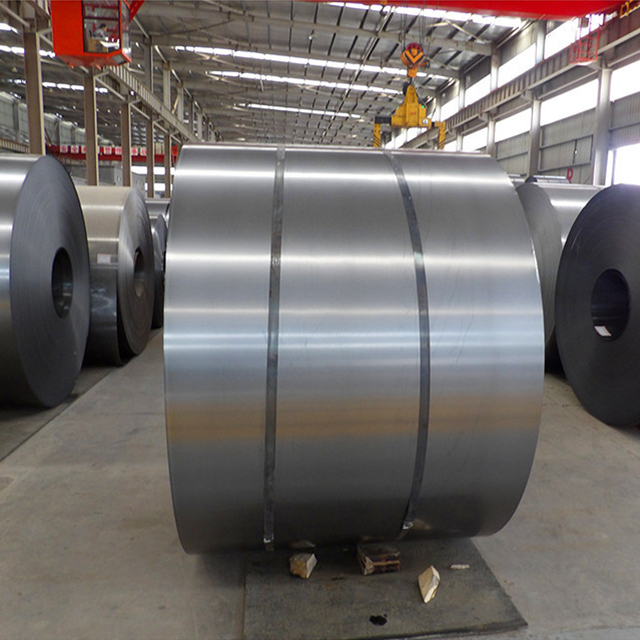

1. Introduction: The Nature of Decarburized Steel

Decarburized steel is a type of steel that has undergone a controlled heat treatment process, resulting in reduced carbon content on its surface. This reduction is usually intentional and is desired for various reasons such as improving the steel's mechanical properties or enhancing its aesthetic appeal. However, one crucial aspect that needs consideration is whether decarburized steel is more susceptible to rusting than non-decarburized steel. In this section, we will provide an overview of decarburized steel and its characteristics.

Decarburization occurs when the carbon atoms in steel diffuse out of the surface layer due to the heating process. This loss of carbon can significantly affect the steel's properties, including its corrosion resistance. Thus, it is essential to understand the relationship between decarburization and rusting to ensure the appropriate use of decarburized steel in various applications.

2. Factors Affecting Decarburized Steel's Resistance to Rusting

In this section, we will explore the factors that influence the rusting behavior of decarburized steel. The understanding of these factors will help industries and manufacturers make informed decisions about the potential risks and benefits of using decarburized steel in different environments.

2.1 Surface Composition and Chemistry:

The composition and chemistry of a steel surface play a vital role in its resistance to rusting. The reduced carbon content resulting from decarburization can lead to a more reactive surface, making it more susceptible to corrosion. Additionally, the presence of other alloying elements and the condition of the steel's surface can also affect its corrosion resistance.

2.2 Environmental Conditions:

The surrounding environment in which decarburized steel is exposed plays a significant role in its rusting behavior. Factors such as humidity, temperature, and the presence of corrosive substances can accelerate the corrosion process. Understanding the impact of these environmental conditions on decarburized steel will enable better decision-making regarding its use in different applications.

2.3 Corrosion Protection Measures:

Implementing appropriate corrosion protection measures can significantly enhance the resistance of decarburized steel to rusting. Techniques like coating, passivation, and cathodic protection can create a barrier between the steel surface and the corrosive environment, reducing the likelihood of corrosion. It is crucial to explore these protection methods to ensure the longevity and reliability of decarburized steel in various settings.

3. Case Studies and Research Findings

To support the discussion on whether decarburized steel rusts, this section presents case studies and research findings that provide valuable insights into the rusting behavior of decarburized steel in different applications and environments. These studies shed light on the practical implications of using decarburized steel and help form a comprehensive understanding of its rusting characteristics.

4. Importance of Maintaining Optimal Carbon Content in Decarburized Steel

Maintaining the optimal carbon content in decarburized steel is crucial for industries that rely on its usage. This section highlights the importance of controlling the decarburization process to ensure the desired mechanical and corrosion properties of  decarburized steel are achieved. By understanding the impact of carbon content on the rusting behavior of decarburized steel, manufacturers can make informed decisions during the steel production process.

decarburized steel are achieved. By understanding the impact of carbon content on the rusting behavior of decarburized steel, manufacturers can make informed decisions during the steel production process.

Conclusion:

In conclusion, understanding the rusting behavior of decarburized steel is essential for industries that utilize steel in their products and processes. By considering factors such as surface composition and chemistry, environmental conditions, and corrosion protection measures, manufacturers can make informed decisions about the suitability of decarburized steel in different applications. Maintaining control over the carbon content during the decarburization process can play a significant role in minimizing the risk of rusting and maximizing the performance and longevity of decarburized steel. Further research is warranted to explore innovative approaches to enhance the corrosion resistance of decarburized steel and expand its potential applications.

add your comment