What is the low carbon steel mold material

Author:ALEX

Abstract:

In this article, we will explore the topic of the low carbon steel mold material. We will provide background information and delve into the four main aspects of this material. By examining its properties, advantages, applications, and manufacturing process, readers will gain a comprehensive understanding of low carbon steel mold material.

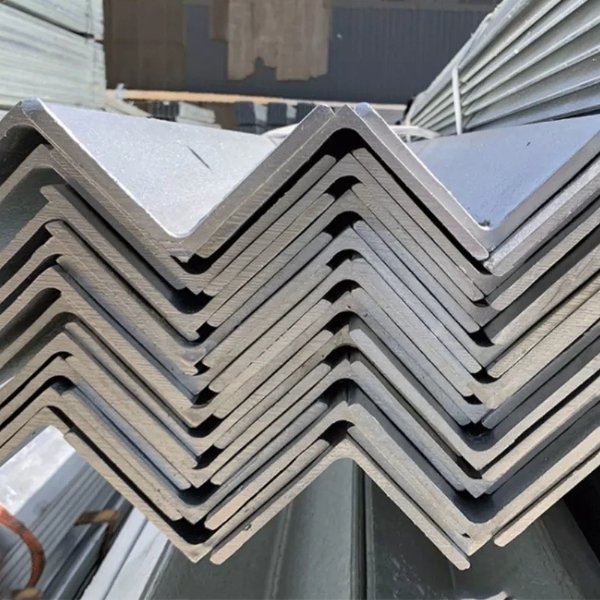

1. Properties of Low Carbon Steel Mold Material

Low carbon steel is a versatile material with various properties that make it ideal for mold manufacturing. Firstly, its low carbon composition ensures excellent machinability and weldability. Secondly, it exhibits good formability, allowing for intricate mold designs. Lastly, low carbon steel possesses high strength and durability, ensuring extended mold life. By understanding these properties, manufacturers can make informed decisions about using low carbon steel for molds.

2. Advantages of Low Carbon Steel Mold Material

Low carbon steel mold material offers several advantages over other materials. Firstly, it is cost-effective compared to high carbon steels or other specialized mold materials. Additionally, it provides excellent thermal conductivity, allowing for efficient heat transfer during the molding process. Moreover, its resistance to wear and abrasion ensures prolonged mold lifespan. These advantages make low carbon steel mold material a preferred choice in many industries.

3. Applications of Low Carbon Steel Mold Material

Low carbon steel mold material finds application in diverse industries, ranging from automotive to consumer goods. In the automotive sector, it is commonly used for manufacturing body panels and structural components. Similarly, the packaging industry relies on low carbon steel molds for producing plastic containers and packaging materials. Furthermore, low carbon steel molds are extensively utilized in the electronics industry for manufacturing intricate parts. Understanding these applications enables manufacturers to determine the suitability of low carbon steel mold material for their specific needs.

4. Manufacturing Process of Low Carbon Steel Mold Material

The  manufacturing process of low carbon steel mold material involves several steps that ensure optimal quality and performance. These include material selection, melting and casting, hot working, heat treatment, machining, and surface finishing. Each step plays a crucial role in shaping the final mold material. By following established manufacturing practices, manufacturers can produce high-quality low carbon steel molds that meet industry standards.

manufacturing process of low carbon steel mold material involves several steps that ensure optimal quality and performance. These include material selection, melting and casting, hot working, heat treatment, machining, and surface finishing. Each step plays a crucial role in shaping the final mold material. By following established manufacturing practices, manufacturers can produce high-quality low carbon steel molds that meet industry standards.

Conclusion:

In conclusion, low carbon steel mold material offers a range of properties, advantages, and applications that make it a popular choice in the manufacturing industry. Its cost-effectiveness, favorable properties, and wide-ranging applications make it a versatile material for molds. By understanding the properties, advantages, applications, and manufacturing process of low carbon steel mold material, manufacturers can make informed decisions when selecting materials for mold production. Continuous research and further exploration of this material can lead to advancements in mold manufacturing and improved performance in various industries.

add your comment